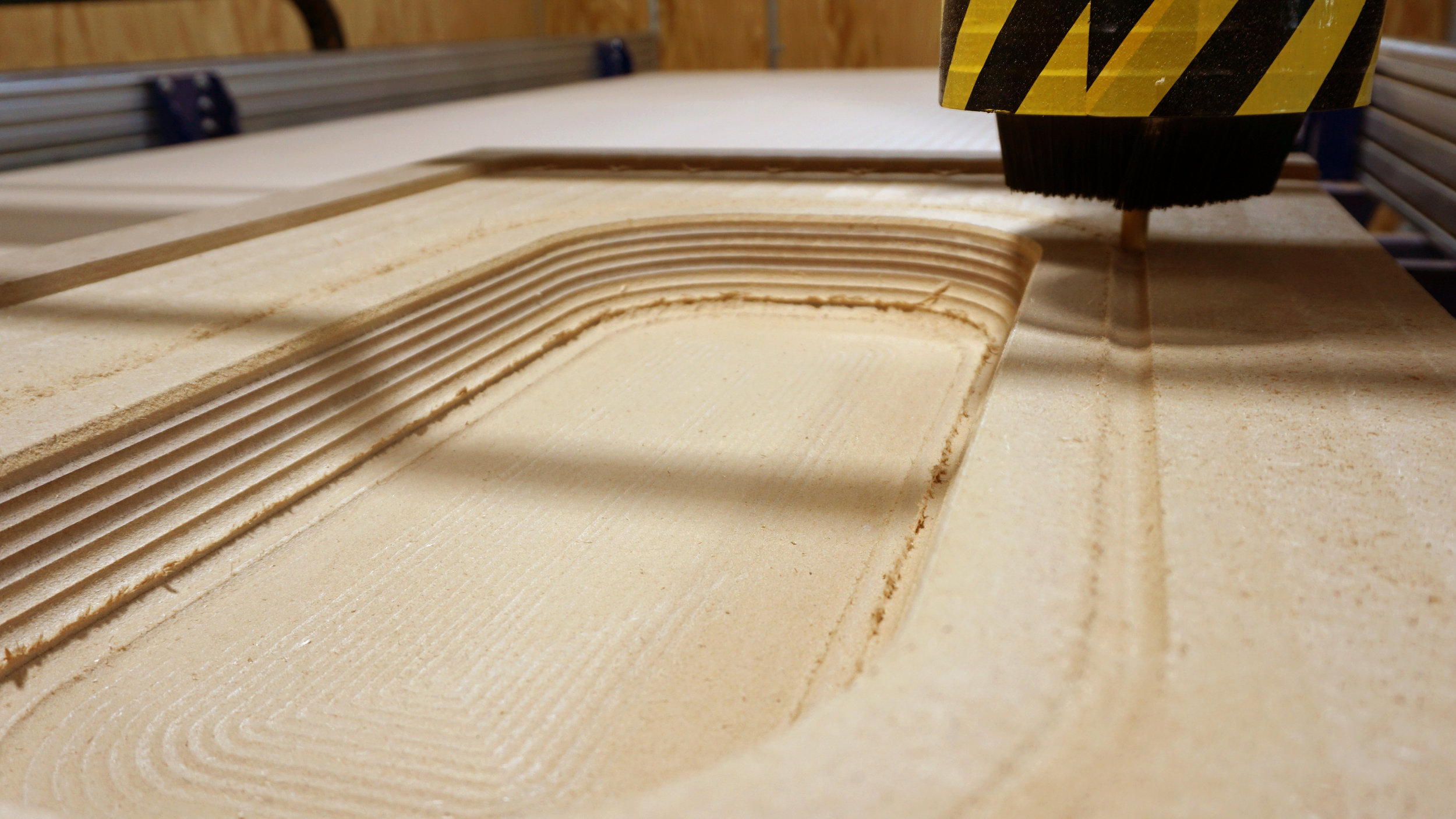

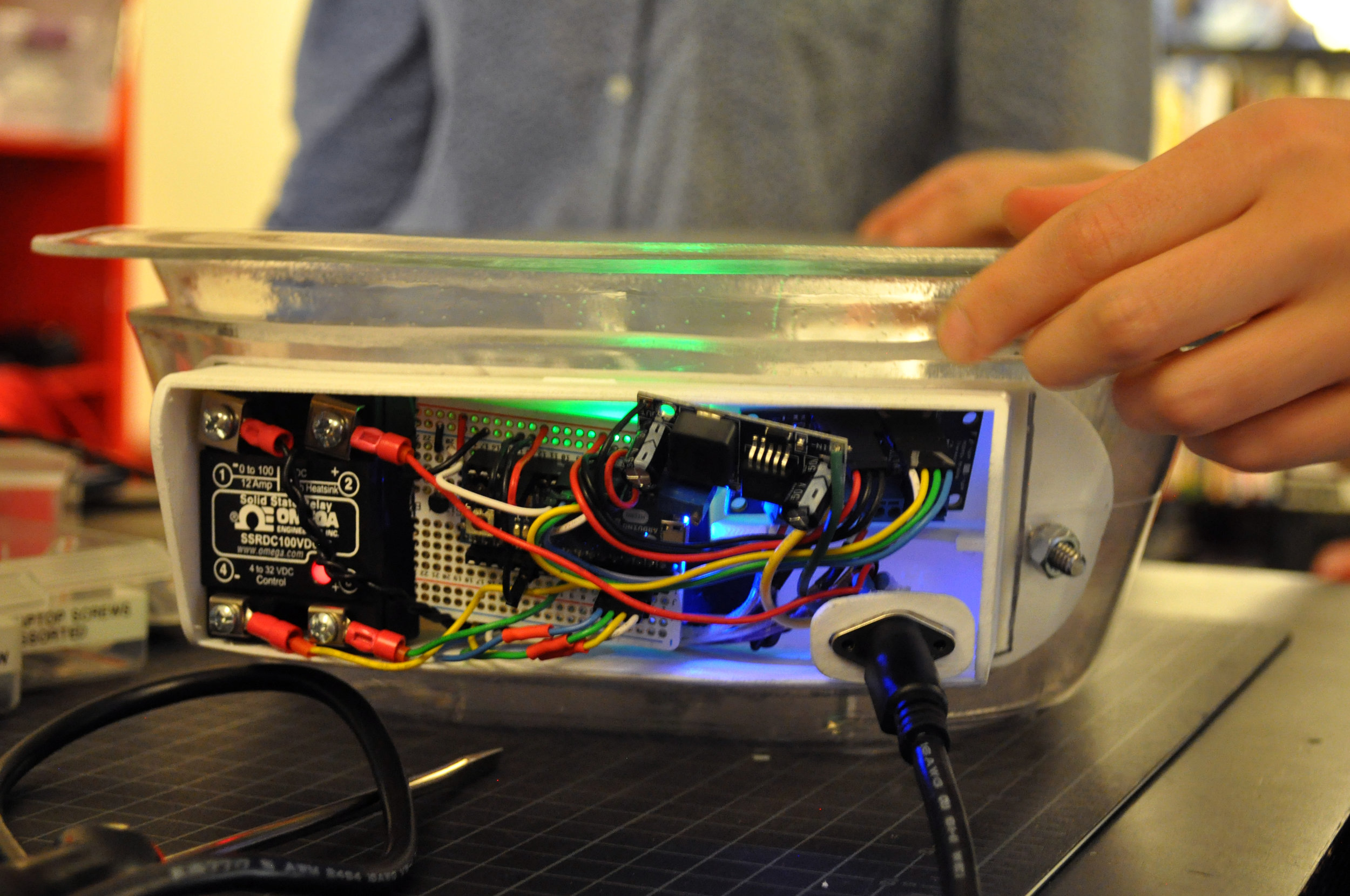

At the end of July, our focus on the Otter summer design sprint shifted from background research and product positioning to prototype fabrication. We have been drinking lots of coffee and racking up the miles, dividing our time between DtM’s Salem studio and the Autodesk BUILD Space in Boston.

Our goal remains the development of an “alpha prototype” of the Otter newborn warmer, which is to say the first generation prototype that integrates both how the product works (warming elements) and how the product looks (user interface and overall aesthetics). A successful prototype will help us test our most critical assumptions about product features, manufacturing methods and price point.

Fabrication is always a blast, second only to field research in the hierarchy of excellent things about working in social impact design. It’s an opportunity to escape our desks, and trade the abstractions of post-it notes and design frameworks for the satisfaction of creating tangible, physical things. Here’s a look at this summer’s build process.